The History Of The Can Opener

Don't have an account?

Creating an account has many benefits: check out faster, keep more than one address, track orders and more.

Let’s rewind back in time to 1795 when French Military leader, Napoleon Bonaparte, offered a substantial prize for anyone who could invent a preservation method that would enable the army’s food to stay fresher for longer. In the early 1800s, an inventor named Peter Durand stepped up to the challenge and invented the world’s first can which was made using wrought iron and tin (that’s some seriously heavy duty metal!) and there you have it, food canning was put into action!

Now, we know what you’re thinking, how could today’s nifty little can openers cut their way through an iron can? Well, to put it bluntly, they couldn’t! The first cans that were ever produced were way, way too thick and, as such, the manufacturer’s suggested method of opening them was with a good old hammer and chisel. As to be expected, having to dig out a hammer and chisel every time you wanted a can of soup wasn’t ideal, nor realistic.

Fast forward to 1858 when iron cans began to be replaced by thinner steel cans, and not long after the first can opener was born. An American inventor, Ezra J Warner developed a blade that pierced the lid of the can, whilst another component sawed around the edge. The only downside to this is that once the lid was removed, it revealed a jagged rim of metal which posed itself as a pretty significant health risk (let’s just say a lot of fingers were lost to this blade in the 1860s).

Despite its downfalls, Ezra Warner’s innovation served its purpose to soldiers during the Civil War, as well as at supermarkets where staff would open cans for customers to take home. Unsurprisingly, it didn’t quite make its way into domestic use!

Many attempts to improve on Warner’s invention were made over the next decade and eventually the basis of the modern can opener that we recognise today came to life, with another US inventor, William Lyman, being the first to create a rotary cutter to cut around the can in 1870.

However, it wasn’t until 1931 when the tooth-wheeled crank design that we use today was patented by a Charles Arthur Bunker, whose design remains as the standard for can-openers to this very day! It was a long old process to get there, wasn’t it?

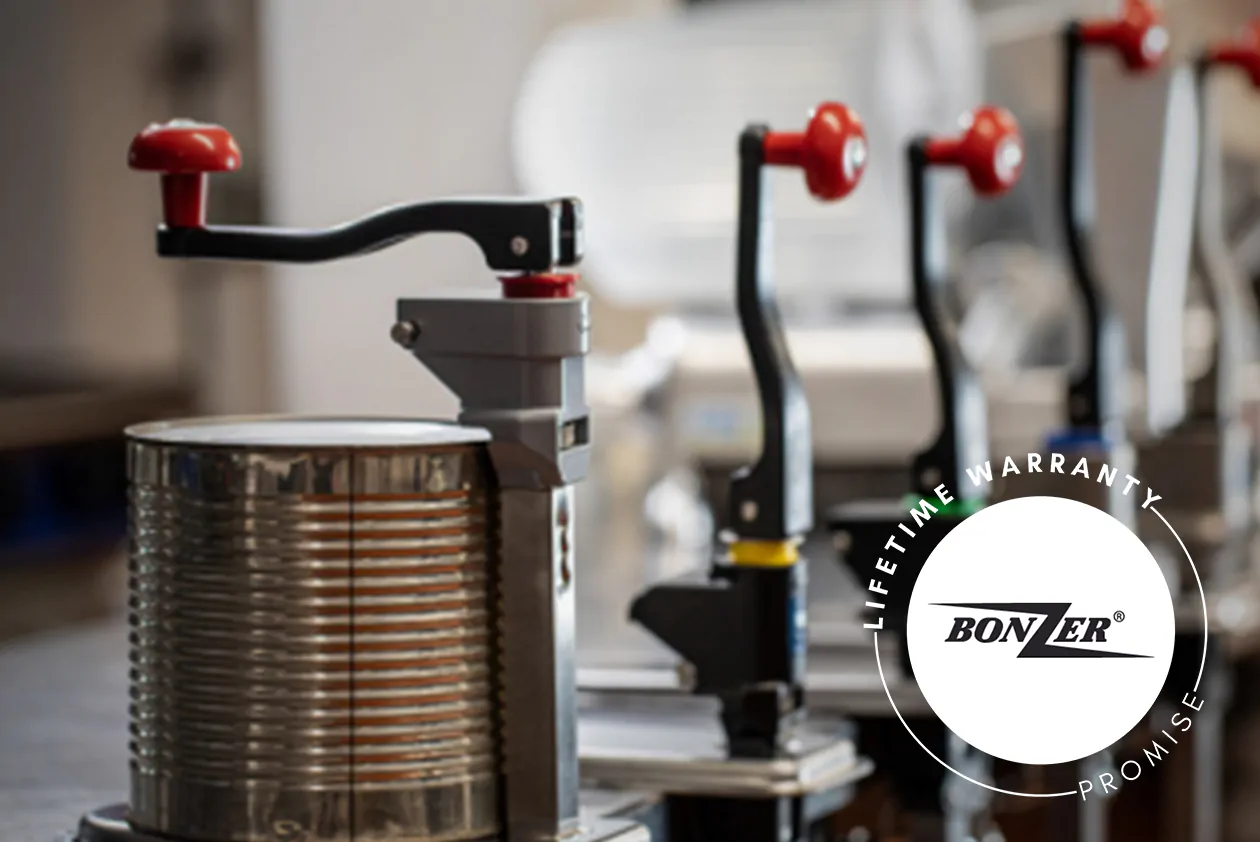

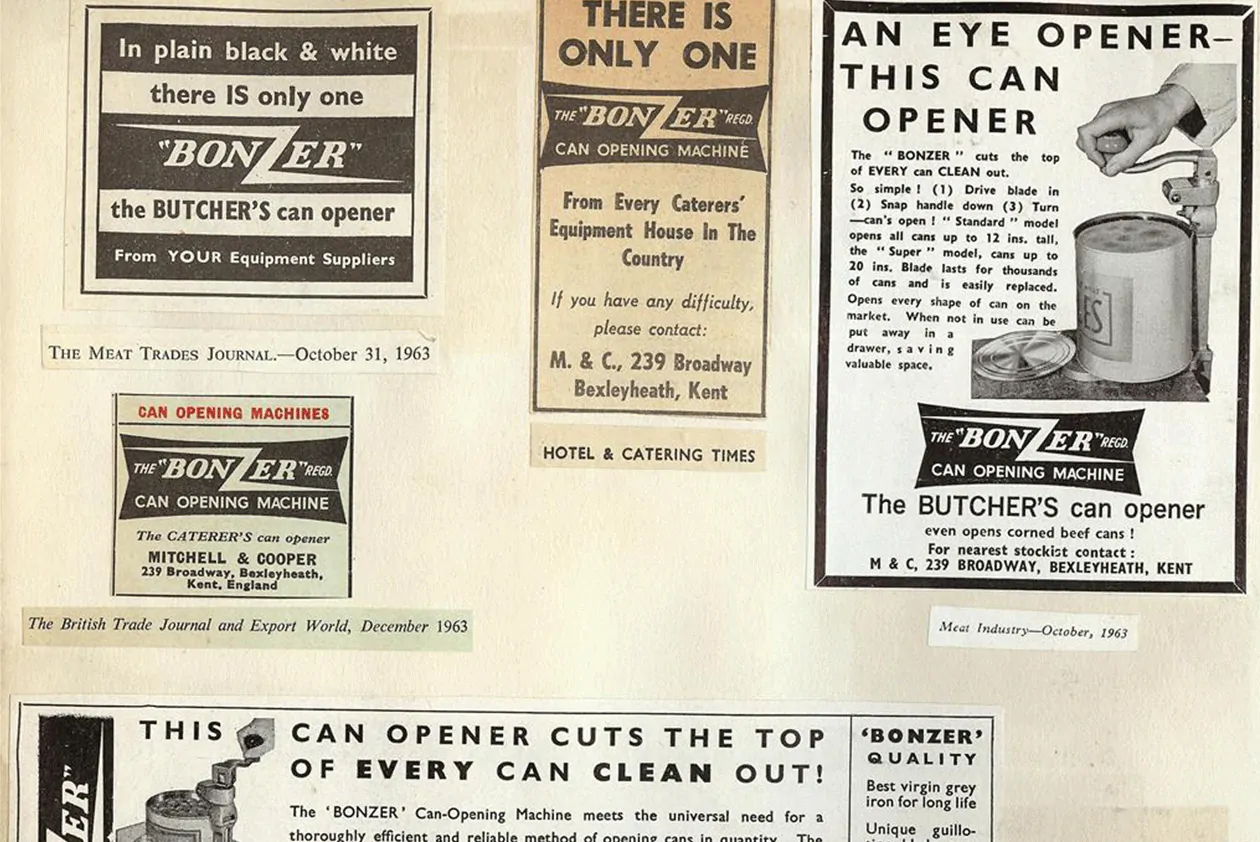

Whilst Bunker’s design was satisfactory for domestic use, it was never the most practical for hotels and restaurants that used cans on a large scale. For such venues, help was just around the corner when in the 1940s, the what is now world-famous range of commercial and industrial Bonzer Benchtop Can Openers, were designed and manufactured for the very first time. As with Bunker’s invention, the Bonzer design has outlived generations and whilst there have been continuous updates and improvements over the last 80 years by the design team at Mitchell & Cooper, the core design concept remains consistent with the first one that was handcrafted all those years ago!

The Bonzer quality and durability has been proven time and time again, not least by the can openers ability to survive 70 Antarctic winters (you can read more about that remarkable story here!). As well as being the go-to product for chefs looking for an efficient and ergonomic can opener for their commercial kitchen, it’s fair to say that the humble Bonzer can opener has become a staple product in professional kitchens over the years.

Whilst Bunker’s design was satisfactory for domestic use, it was never the most practical for hotels and restaurants that used cans on a large scale. For such venues, help was just around the corner when in the 1940s, the what is now world-famous range of commercial and industrial Bonzer Benchtop Can Openers, were designed and manufactured for the very first time. As with Bunker’s invention, the Bonzer design has outlived generations and whilst there have been continuous updates and improvements over the last 80 years by the design team at Mitchell & Cooper, the core design concept remains consistent with the first one that was handcrafted all those years ago!